Share this

Swagelok T60M Series: Ideal Valve for Thermal Service Applications

by Derek Green on Tue, Apr 02, 2024 @ 08:04 AM

Here we'll look at the design and ideal uses of Swagelok's Thermal Service Ball Valve (T60M Series). With its innovative metal seat, this special purpose valve is designed to maintain a seal with a minimum seat load against the ball.

The Swagelok T60M Series thermal service ball valve features a spring-like metal seat designed for maintaining a seal with minimum seat load against the ball. It is available in 316 stainless steel or carbon steel, with Grafoil packing and alloy X-750 seats.

This valve is specifically intended to resist contamination in thermal liquid applications and is suitable for use with high-viscosity thermal fluids. (Note: we advise against using the valve with hot gases or low-viscosity fluids, as these may remove the factory-applied lubricant, leading to premature seat wear.)

The Swagelok T60M Series thermal service ball valve exceeds performance criteria set by the Fire Test Standard API 607, 6th edition. This certification underscores the valve's capability to maintain its integrity and functionality in extreme conditions, confirming its suitability for applications where safety in the face of fire hazards is top priority.

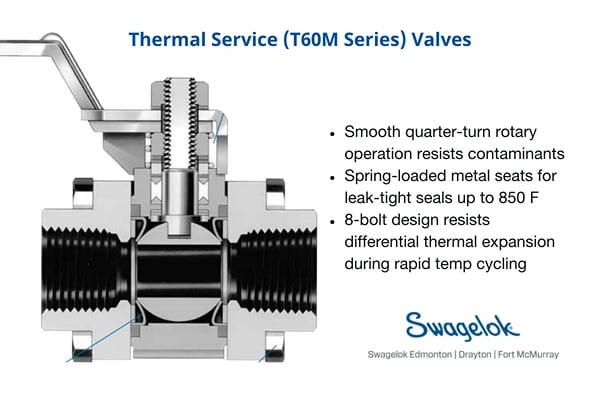

Design features

The valve's smooth, quarter-turn rotary operation resists outside contaminants and reliably contains thermal liquids, preventing leaks and ensuring safe transport of high-viscosity fluids. Its spring-loaded metal seats provide leak-tight sealing up to 850°F (454°C) and down to -65°F (-53°C), and work effectively in both low- and high-pressure systems up to 1000psi (68.9 bar), enhancing reliability in high-temperature applications.

Featuring encased 8-bolt construction, the valve counters differential thermal expansion during rapid temperature cycling, maintaining structural integrity and reducing the risk of leaks or damage from varying expansion rates.

All Swagelok's thermal service ball valves undergo testing with pure nitrogen at 50 psig (3.4 bar) to ensure leak-tight integrity of the ball seats, as per FCI 70-2 Class VI specifications. Stem packing and body seals are checked for no visible leakage using a liquid leak detector.

Seal kits

Seal kits for T60M valves include an array of components: the ball, seats, packing, flange seals, stem bearings, back seats, packing supports, stem springs, lubricant, sealant, and instructions for use.

Download 60 Series Ball Valve catalogues and more

Get literature on 60 Series, One-Piece Instrumentation, and several other ball valves.

Download Valve Selection & Sizing Resource Collection

Get our STAMPED Method of Valve Selection Briefing, pocket guide, brochure, and articles.

Getting help with valves

Requesting evaluation and advice from a Swagelok Edmonton Field Advisor is a great way to start any project involving fluid systems. We listen to understand your priorities, gather information on your systems and routines, conduct onsite inspections as appropriate, and offer detailed recommendations. Our goal is to help identify opportunities to increase reliability while lowering your operating costs and minimizing risks. Both onsite and remote support are available.

Related articles

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)