Products > Welding Systems

Swagelok Welding Systems

Download Swagelok® catalogues and local PDFs. Learn about fabrication & assembly services, training, and more. Tel: 780-437-0640.

Download Essential Welding Systems Literature

Swagelok Welding Systems & Components

Scroll below to learn about the Swagelok M200 welding system power supply, weld heads, and related offerings. Want a hand selecting? Please use the "request details" button.

.webp)

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

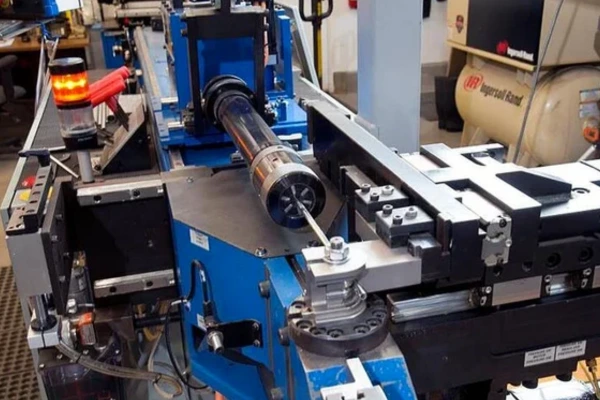

Designed for Precise, Repeatable Orbital Welds

How does our system consistently deliver precise, repeatable GTAW for tubing and pipe? We have continuously improved it over 40 years based on customer feedback. Today the M200 system offers a user-friendly touch screen, real-time monitoring, automatic documentation and other features.

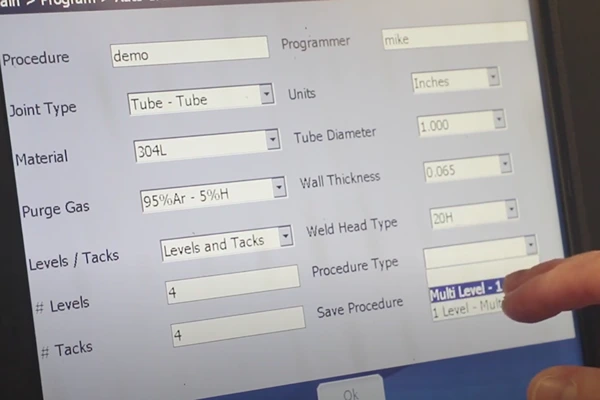

Auto Create

The Auto Create function simplifies program creation for welding procedures. Users only need to input the procedure and programmer names; the rest is selected from a drop-down menu that considers the material, purge gas, and joint type. This function makes it easy to benefit from Swagelok's extensive knowledge in orbital welding, which is integrated into the equipment.

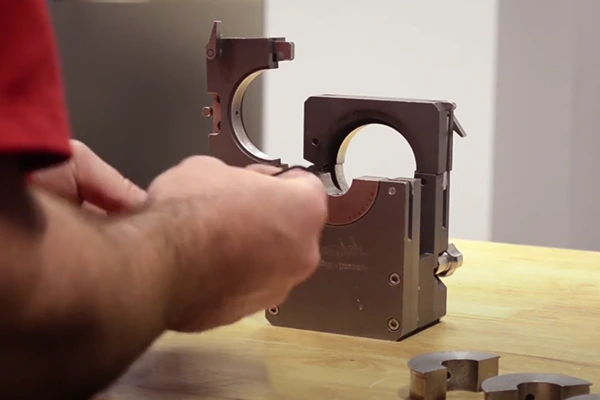

Fixture Block & Collet Installation

Optical Speed Control

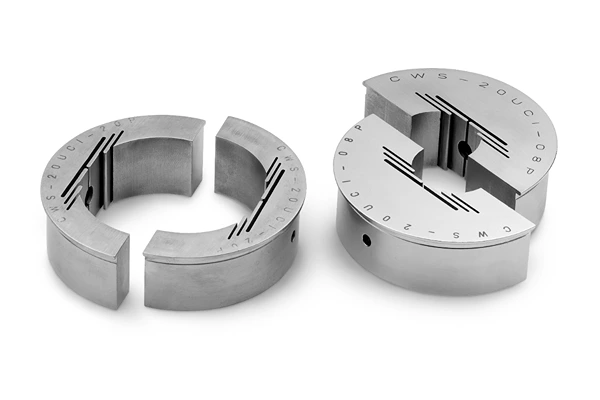

Swagelok weld heads have optical speed control without the need for a tachometer or calibration. Using weld head extension cables, you can perform welds farther away from the power supply. Weld on tubing with outside diameters between 1/16 and 4 in. and 2 mm to 114 mm. The polarized power connector ensures proper weld head/power supply connection.

Choice

Fabrication Option

Field Advisory Option

Local

Quick Turn

Rental Option

Technical Support

Training Option

Warranty

Tube Bending Services, Material Selection & More

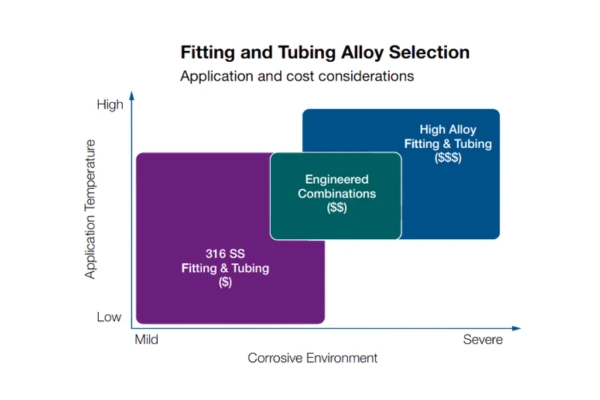

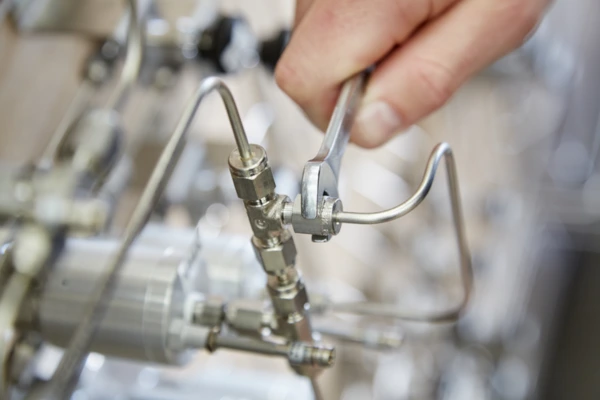

Our team is ready to help with selecting and sizing tubing, including choosing materials of construction for compatibility. We can also provide exact lengths of tubing in any quantity. Tube bending services are available too.

Selection and Support

Tube Bending (CNC, Hand, Etc)

Pre-Fabricated Assemblies

Download Swagelok's Materials Selection Guide

Saving with Fabrication & Assembly Services

We design, fabricate, and test fluid system assemblies for customers, right here in Edmonton.

We combine safe, reliable Swagelok components to produce assemblies for gas distribution, grab sampling, mechanical seal support, and other uses. We also build hose, bend tubing, and make filter retainer assemblies, for example. Design support, fabrication, assembly, and pressure testing are included! We can be onsite at installation too.

We offer regularly scheduled training courses at our Edmonton facility, as well as private customized training. Among the custom options is an M200 Welder Introduction. Topics include the basics of autogenous welding, introduction to the M200, setup and teardown of the M200, welding, and troubleshooting. Instrumentation technicians, pipe fitters, millwrights, welders, managers, and quality control personnel especially benefit from this training. Successful participants can earn a Swagelok Certificate of Completion.

Download Materials for Oxygen Service Resource Collection

Swagelok Gas Distribution Program

Problems with gas distribution can mean losing gas, low quality product, production slow downs, and safety hazards. We offer a solution that combines pressure control advisors and fully assembled gas distribution systems.

We offer analysis to inform regulator selection, identify system upgrades, and produce solutions. We can inspect, consult, advise, then deliver a fully engineered system built with minimal threaded connections to avoid leaks, clearly labeled for safety and functionality, that is easy to operate and service. Your system is assembled and tested before it leaves our shop, and backed by Swagelok's strong warranty. See the next section for literature on this option.