Share this

FAQ: Which is the Correct 60 Series Ball Valve?

by Derek Green on Mon, Jan 15, 2024 @ 11:01 AM

Ball valves are a practical and economical way to control flow in a wide variety of applications, and Swagelok's 60 Series offers a highly flexible design in a broad range of sizes. Try our 7-step STAMPED method to determine the best one for your application.

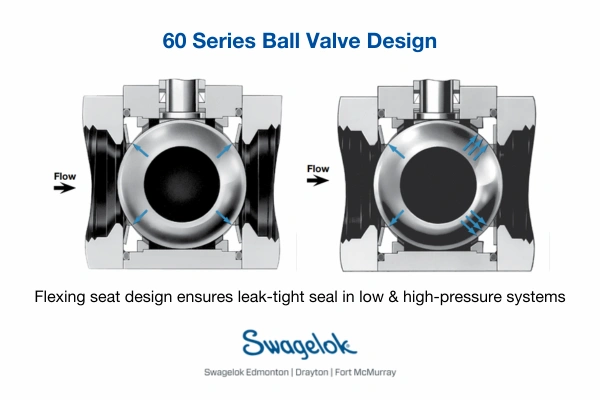

Internal features set our 60 Series valves (illustration and video below) apart. The stem bearing has serrations that will hold lubricant, reducing torque and extending the lifespan of the valve. We use a live-loaded seat, in which two washers are constantly adjusting in order to push the load down into the packing system. It creates an even seal without pressure.

Our swing-out design allows for changing packing while leaving the valve inline. So your line will be back up and running in much less time than when using traditional valves.

Try this STAMPED selection method to select the best 60 series valve for you:

For details we recommend visiting our new 2024 Swagelok Valves page, where you can get our Valve Selection and Sizing Resource Collection, browse FAQs, and get other resources.

The video goes through each of the seven steps, but I'll underscore a few points:

Begin by determining the valve size to match your system’s flow capacity. The 60 series offers various sizes and orifice dimensions tailored to different flow rates.

When selecting for temperature, match the materials to the media and environmental temperatures. Swagelok's 60 series valves, for instance, come with reinforced PTFE seats and packing, and offer options like fluorocarbon seals for diverse temperature needs.

Also consider the application: the 60 series valve's adaptability allows for configurations suitable for a wide range of industrial uses, with special configurations for unique conditions such as steam service or high-temperature exposure.

Ensure the valve materials are compatible with your system media to avoid corrosion or embrittlement. Also, consider the pressure, taking into account both the operational pressure and the valve's maximum pressure rating to maintain safety. The valve assembly should have the proper rating for your operational needs, and you should never exceed the valve's design pressure.

For end connections, choose options that suit your system’s pressure and temperature demands and that are correctly sized to prevent leaks and ease installation.

Lastly, assess your valve requirements in terms of timing and quantity. Our team is ready get you the necessary parts when you need them.

Getting help with valves

Field Advisory Services

Swagelok Edmonton offers experts trained to help customers take action on fluid system challenges. If you'd like to double-check your selection with our advisors, we are here to help. You can also talk with our Field Advisory team about analytical instrumentation, compressed gas leaks, seal flush systems, applications support, and more.

(In a hurry or prefer a phone call? Please call 780.437.0640 Mon-Fri 7:30am-5:30pm MT.

Design Support & Assembly Services

Some customers opt to get a fully built assembly that includes the right valve(s). The Custom Solutions team here at Swagelok Edmonton builds analytical subsystems, gas distribution systems, grab sampling systems, hose assemblies, regulator assemblies, and much more. Below is just one example, the Steam Lance assembly featuring the 60 Series Ball Valve:

Your assembly arrives ready to install, and is covered by the same warranty as our individual parts. Projects include design support, parts, fabrication, assembly, testing, documentation, and installation support.

|

Valve Selection Best Practices Resource Collection

In one step get our STAMPED Method of Valve Selection Technical Briefing Video, relevant catalogue, pocket guide, and brochure; and articles by our local team.

|

Related articles

Share this

- Field Advisors (105)

- Local Services (105)

- Training & Events (86)

- Fittings (81)

- Valves (67)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (58)

- Resources - Downloads (43)

- Hose & Flexible Tubing (40)

- Frequently Asked Questions (37)

- Oil & Gas (36)

- Cost Savings (34)

- Regulators (34)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Safety (9)

- winterization (9)

- Rentals (6)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (2)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)