Learn more about choosing the right industrial fluid systems.

With the ever-evolving oil and gas industry, it is important to place focus on safety, operational integrity and reliability, and environmental impact. The best practice for addressing these challenges is to implement equipment designed with these challenges in mind—minimizing risk and optimizing efficiency and reliability. When you purchase Swagelok products via Edmonton Valve & Fitting, you connect to a technology leader who will provide you with standardization, product selection assistance, and vendor-managed inventory, leaving you more time to focus on what’s important: operations.

Smooth operations and maximized uptime are dependent on high-quality, corrosion-resistant fluid system components and intuitive, reliable, and safe industrial fluid systems. Swagelok employs the principles of safety and reliability by design to ensure seamless operations in every industrial fluid system. Take advantage of Swagelok’s top-of-the-line components, fully configurable and customizable industrial fluid systems for oil and gas, and Edmonton Valve & Fitting’s deep local knowledge of oil and gas applications in upstream, midstream, and downstream operations in northwestern Canada.

.jpg)

For more than 50 years, Edmonton Valve & Fitting has been a local supplier of Swagelok products for oil and gas sectors in northern and central Alberta.

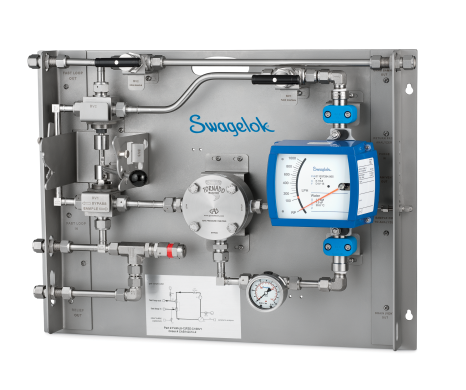

Whether you are employing conventional oil and gas production techniques or steam-assisted gravity drainage (SAGD), the seal support system is the basis for safeguarding all rotating equipment. Accounting for almost 40% of pump failures, seal failure is a major problem that can lead to unplanned downtime.

Seal support systems protect rotating equipment from damage by providing lubrication to seal surfaces, controlling pressure and temperature in the seal chamber and seal itself, and flushing the seal of contaminants and/or residue. These systems also prevent the system process fluid from leaking into the atmosphere, which is essential for the safety of the operator and for maintaining continuous operations. If a seal is leaking, time must be taken to address this leak point in order to resume normal operations; thus, a reliable and robust seal support system is the ticket to maximizing uptime.

Seal support systems protect rotating equipment from damage by providing lubrication to seal surfaces, controlling pressure and temperature in the seal chamber and seal itself, and flushing the seal of contaminants and/or residue. These systems also prevent the system process fluid from leaking into the atmosphere, which is essential for the safety of the operator and for maintaining continuous operations. If a seal is leaking, time must be taken to address this leak point in order to resume normal operations; thus, a reliable and robust seal support system is the ticket to maximizing uptime.

During the upstream process, it is important to regularly sample the system process fluid as well as any water that may be used in the process, such as recycled water used for SAGD. Around 90% of the water used for SAGD must be recycled, treated, and reused in the boiler to provide the necessary steam to heat bitumen underground. Sampling this treated water is crucial for boiler efficiency. If the water is not properly treated, hard scale build-up may develop on the inside of the boiler tubes, leading to increased fuel consumption and increased temperatures—which can often result in mechanical failure. The solution here is to have a reliable grab sampling system that provides timely representative samples to best inform the process.

During the upstream process, it is important to regularly sample the system process fluid as well as any water that may be used in the process, such as recycled water used for SAGD. Around 90% of the water used for SAGD must be recycled, treated, and reused in the boiler to provide the necessary steam to heat bitumen underground. Sampling this treated water is crucial for boiler efficiency. If the water is not properly treated, hard scale build-up may develop on the inside of the boiler tubes, leading to increased fuel consumption and increased temperatures—which can often result in mechanical failure. The solution here is to have a reliable grab sampling system that provides timely representative samples to best inform the process.

Pumps and compressors are relied upon to transport oil and natural gas through pipelines. To ensure integrity, pumps and compressors should be thoroughly tested. Edmonton Valve & Fitting is equipped to support you through any midstream operations—from fluid transfer to custody transfer.

Finding the right seal support system for midstream operations means finding a system that maximizes overall reliability and provides extended maintenance intervals to keep processes running smoothly and efficiently. This means finding a system designed with reliability and maintainability in mind. Ease of operation and maintenance means less risk of operator error.

During fluid transfer, and especially custody transfer, the sampling and testing of oil must be efficient. Due to the high value and large volume of crude oil, it is important that the sampling and measurement systems are accurate. During this process, the oil must move through the pipelines at high flow rates to ensure a representative sample is attained. A fast loop sampling system should be utilized, as it is designed to handle high flows in the transport lines to reduce time delays for online analyzers. In this stage, all measures should be taken to ensure the fastest response time while also minimizing sample waste. Edmonton Valve & Fitting provides intuitively designed customizable fast loop modules with minimal connections to reduce the number of leak points.

During fluid transfer, and especially custody transfer, the sampling and testing of oil must be efficient. Due to the high value and large volume of crude oil, it is important that the sampling and measurement systems are accurate. During this process, the oil must move through the pipelines at high flow rates to ensure a representative sample is attained. A fast loop sampling system should be utilized, as it is designed to handle high flows in the transport lines to reduce time delays for online analyzers. In this stage, all measures should be taken to ensure the fastest response time while also minimizing sample waste. Edmonton Valve & Fitting provides intuitively designed customizable fast loop modules with minimal connections to reduce the number of leak points.

Industrial fluid systems for oil and gas are also critical in downstream operations, especially in refineries. Rotating equipment failure and the inability to obtain representative samples are two of the greatest challenges for Canadian refineries. Having reliable and safe seal support and grab sampling systems is important for maximizing uptime.

Often, especially in older refineries, seal support systems may be overlooked. However, these systems are just as important in downstream processes as they are in upstream and midstream. Without a properly designed and installed seal support system, seals are certain to have a shorter life cycle or potentially cause a mechanical failure. This is particularly apparent in centrifugal pumps used during the refining process. If a seal causes a failure in the system, the entire operation comes to a halt, as refineries rely heavily on these pumps.

Obtaining samples in oil and gas refineries helps process engineers make informed decisions to improve the efficacy of the refining process. These sampling systems should be designed in such a way that a representative sample can be acquired and it is not contaminated by previous samples in the line.

Industrial fluid systems for oil and gas are vital components in safeguarding equipment for all upstream, midstream, and downstream processes. Partnering with Edmonton Valve & Fitting offers you the combination of global expertise and local support from highly experienced individuals through our Field Advisory Services.

To find out more about how Edmonton Valve & Fitting can provide high-quality industrial fluid systems for your oil and gas needs, contact us through our website or by calling 780-437-0640.

From single components to complex fluid handling systems we have the products, expertise, and resources to meet your needs.

Learn more.

Edmonton Valve invites you to take advantage of Swagelok Field Advisory Services. Getting started creates no cost or obligation.

Get started today.

Edmonton Valve & Fitting Inc. services northern and central Alberta, Canada. Look for a location near you.

For 50 years Edmonton Valve has provided Swagelok products and expert support to companies in northern and central Alberta.

Click to see our entire line card.

Expand your knowledge with updates, tips, and resources crafted by one of our 65+ local experts. Subscribe now.

Swagelok is a $2B developer of industrial fluid system products and services. Swagelok Edmonton is an authorized Swagelok Sales and Service Centre serving Canadian companies in clean energy, chemical, oil and gas, and other industries. Proud member of the Canadian Council for Aboriginal Business.

Tel: 780-437-0640.

Swagelok Edmonton values your privacy. This website uses cookies to enhance user experience and analyze performance and traffic. Our policies are posted here.

Login/Register | Privacy | Safe Selection | Centre Locator | Sitemap | Legal

© 2012-2024 Edmonton Valve & Fitting Inc.