Products > Measurement Devices

Swagelok Measurement

Take Swagelok® PDFs, scroll options, and browse FAQs with local tips on gauges, flowmeters, identifying threads, and more. Tel: 780-437-0640.

Download Essential Measurement Devices Literature

Get catalogues on flowmeters, gauges, thermometers, transducers, and thermowells.

Accurately Measure Industrial Processes and Conditions

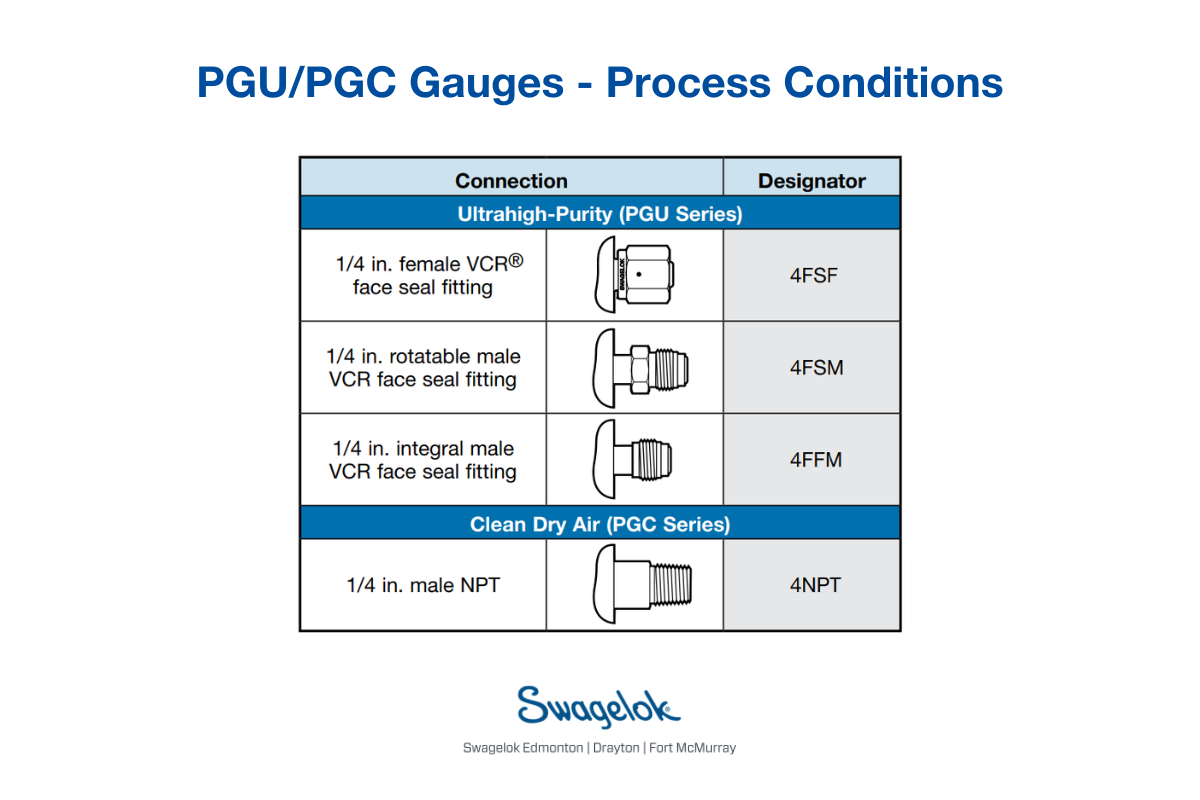

Swagelok gauges provide accurate pressure measurement for industrial, ultrahigh-purity, and sanitary applications. They are offered in a wide range of pressure ranges, dial sizes, connections, mountings, and options to support a wide range of customer requirements.

.png)

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

Why Specify Swagelok Measurement Devices?

Why do engineers specify Swagelok devices? Because using other brands risks unpredictable quality, frequent maintenance, and safety hazards. Here are examples of Swagelok's thoughtful designs:

Ultrahigh-Purity Pressure Gauges

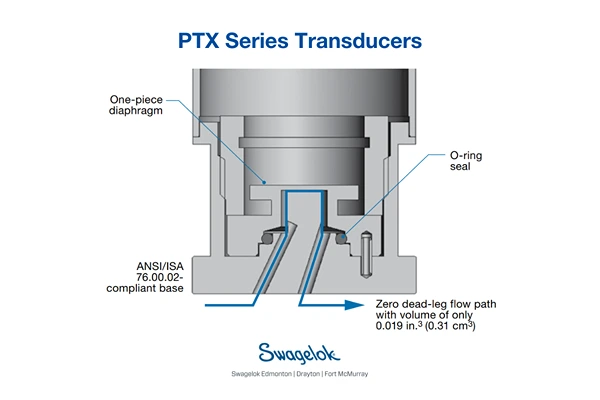

Intrinsically Safe Transducers

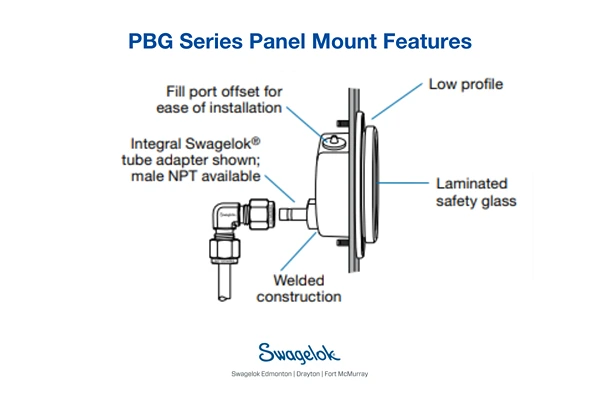

Pressure Gauges for Panel Builders

Certifications

Expertise

Guarantee

Inventory

Manufacturing

Materials

Reliability

Safety

Training

Minimizing Component Installation Errors

We train those who develop, install, inspect, maintain, operate, or buy parts for fluid systems.

We guide engineers, installers, technicians, procurement specialists, and quality managers in techniques for designing, implementing, and maintaining reliable, cost-effective fluid systems. Every seminar is led by one or more Swagelok-certified Trainers and some offer a Swagelok Certificate of Completion. Tube Fitting Essentials, FK Essentials, and Inspection Essentials are three examples of the seminars we offer.

Grab Sampling Solutions

Configurable. Local. Reliable.

Swagelok grab sampling systems satisfy gas and liquid non-slurry sampling service in a consistent, reliable package. Two system types allow for capture into one of two types of containers. To learn more watch this video and download the literature in the next section.

Grab Sampling Best Practices Resource Collection

Get our Grab Sampling Best Practices Technical Briefing Video; relevant application guide, sample report, program brochure, and links to articles by our local team.

Frequently Asked Questions

Following 5 rules will help make sure you're using gauges correctly:

- Double gauge pressure over system pressure.

- Liquid fill where vibration is present.

- Always use a restrictor when pressure spikes are present.

- Hang a gauge upside down when high pressures and flows are present

- Never mount the gauge directly above a high temperature source

Each of these rules is explained in our article The Five Laws of Swagelok Gauges.

Need help selecting a gauge, evaluating gauge installation or designing a fluid system? Please use a green button on this page to get in touch.

Swagelok's Instrumentation Tool Kit has all you need to assemble 3 sizes of Swagelok tube fittings: 1/4 inch, 3/8 inch & 1/2 inch. This includes hand tube benders, deburring tool, tube cutter, ratchet wrenches, pre-swaging tools, inspection gauge, tee wrenches, and the Swagelok Tube Fitter's Manual.

This kit keeps your tools safe, both in the travel to and from job sites, and safe from other elements in your surroundings. If you want to learn more, send us a note and we would be happy to get you started.

See an example and learn more in our article Stay Organized with Edmonton Valve's Instrumentation Tool Kit.

Even for some of the simple applications -- you want a precise measurement. The most basic measurement device is the variable area flowmeter. It measures the flow rate of liquids and gases by means of a tapered tube and float. The float is pushed up by increasing fluid flow and pulled down by gravity as fluid flow decreases. No external power is required, though Swagelok does offer some electronic options.

Once you have flowmeters in place, it's a good idea to follow up with a calibration program, checking every so often that you are still getting accurate readings. Other than that, very little maintenance is required.

Learn more in our article Going with the Flow: When Are Swagelok Area Flowmeters Needed?

Need a hand determining whether a flowmeter is needed, or selecting one for your application? Please use a green button on this page to get in touch.

Like you, we can't tell thread size and thread pitch on a component just by looking at it. But we can provide calipers, combs, and guides that help with identifying threads.

When you look at a thread, you'll see peaks (called crests) and valleys (called roots). The part in between the crest and the root is called the flank. The first thing you want to find out is whether the crests are all the same diameter. That would mean you have straight threads. So we get out our calipers and measure the first, fourth and last crests. If the measurements are the same, you have straight threads. If you get three different measurements, you have tapered threads.

You can find more tips in our article Calipers, Combs, And Guides Help Make Sense of Threads.

Need help identifying threads? Please use a green button on this page to get in touch.

Swagelok's Field Station Module is a pre-engineered, fully built subsystem that moves samples to the analyzer faster. When this pre-engineered subassembly is placed directly off the supply tap, it lowers the pressure of a gas as soon as possible.

In addition to giving you a fast response time, the field station module reduces condensation in the sample. Higher pressure will squeeze out any water in a gas, causing condensation issues. With a lower pressure, you don't get that change in phase. Lower pressure also provides a safer environment for your personnel.

More information is available in our article Swagelok’s Field Station Modules Are Compact and Ready to Go. Please use a green button on this page to get in touch if you'd like a demo or details.

Here are five common mistakes and the problems they can cause. Do any of these sound familiar?

- Your gas sampling system has too much volume upstream of the first regulator.

- Your liquid sampling pressure is too low.

- You’re sampling from a stagnant line.

- Your vaporizer is too hot.

- Your sample flow is too slow.

Each of these issues is explained in our article Watch for These Sampling System Mistakes That Can Hurt Your Operations.

Please use a green button to get in touch about how we can help you diagnose and address sampling system issues.

For personalized, up-to-the-minute answers to sales and support questions, please use green buttons on this page to request details/quote.

If you prefer to find answers yourself, visit products.swagelok.com, register for an account, and start exploring. Anyone can register, and completing the entire registration form will allow you to view pricing, order online, request quotes, store favorite products, assign customized part numbers, and save or forward your shopping cart. Register or log in →

For 24x7 technical support call 780-237-7109. Request the on-call Field Advisor to discuss your technical question.

For 24x7 parts call 780-437-0640. Select "Emergency Service". Request to buy outside regular hours.

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.