Products > Tubing

Swagelok Tubing

View types and take Swagelok® catalogues. Browse FAQs with local tips. Learn about our tube bending service. Tel: 780-437-0640.

Download Essential Tubing Literature

Swagelok Tubing for Every Industrial Application

With 200 active patents, Swagelok supports the most critical applications and industries. You can find our tubing in tens of thousands of industrial plants worldwide. Here are some of your options:

%20and%20High-Purity%20Stainless%20Steel%20Tubing.webp)

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

Tubing Selection & Tube Bending Services

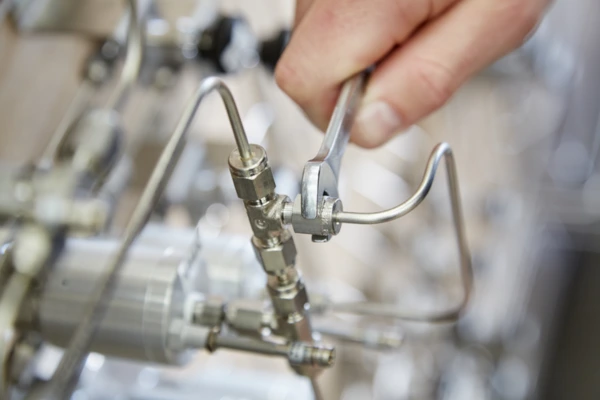

The unsurpassed quality of Swagelok tubing derives from extraordinarily high quality materials, thoughtful design, and manufacturing controls. Pair that with our local services like tube bending, training seminars, and selection support, and you get even more value.

Selection and Support

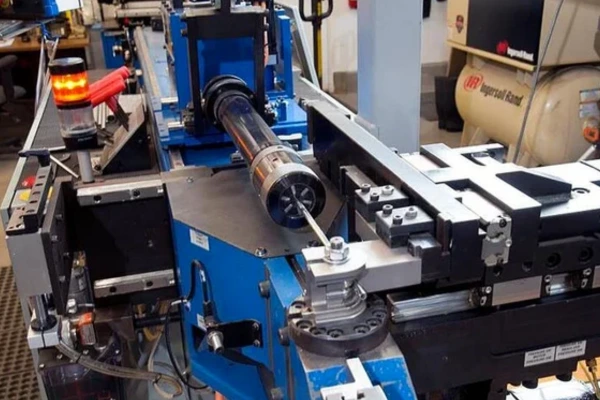

Tube Bending (CNC, Hand, Etc)

Pre-Fabricated Assemblies

Certifications

Expertise

Inventory

Manufacturing

Reliability

Training

Download Swagelok's Materials Selection Guide

Improve Tube Bending Skills with Swagelok Training

A seminar on how to choose correct tubing and fittings for the site and properly handle, prepare, and install components.

Students earn foundational knowledge that ensures system integrity and minimizes leakage risks. The course covers proper tube selection, cutting, and deburring; assembly of Swagelok tube fittings; and gauging a tube fitting assembly. Bending tube helps to eliminate mechanical connections, which can be a source for leaks in traditional piping systems. Instrumentation technicians, pipe fitters, millwrights, managers, and quality control personnel especially benefit from this training. If participants pass exams, they are eligible for a Swagelok Certificate of Completion valid for 3 years.

Fully Built Gas Distribution Systems

Problems with gas distribution can mean losing gas, low quality product, production slow downs, and safety hazards. We offer a solution that combines pressure control advisors and fully assembled gas distribution systems.

We offer analysis to inform regulator selection, identify system upgrades, and produce solutions. We can inspect, consult, advise, then deliver a fully engineered system built with minimal threaded connections to avoid leaks, clearly labeled for safety and functionality, that is easy to operate and service. Your system is assembled and tested before it leaves our shop, and backed by Swagelok's strong warranty. See the next section for literature on this option.

Gas Distribution Best Practices Resource Collection

Frequently Asked Questions

When selecting a type and size of tubing for a job, we recommend you consider:

- Surface finish

- Material

- Hardness

- Wall thickness

With just those four factors you can come up with thousands of permutations. To help you narrow down your choices, Swagelok has developed tubing data sheets. There are separate sheets for more than a dozen different materials such as carbon steel, copper, aluminum and a variety of alloys.

Watch out for bends. When installing fittings near bends in the tubing, you need to make sure that you leave enough straight length in the tubing to properly bottom the tubing out in the fitting. How much is enough? The tubing data sheet provides a handy chart to help you.

Learn more in our article Which Kind of Tubing is Right for Your Application?

To receive our Tubing Data Sheet please see the "Download Essential Tubing Literature" option at the top of this page. Need a hand? Please use a green button to get in touch.

Tapered pipe threads are one of the most common end connections found in industry. They are relatively simple to make up, however they always need a sealant since there are designed-in gaps between the male and female threads.

This video covers preparation, tape size, wrapping procedures, and subsequent tightening.

Learn more in our article Skill: Applying PTFE Tape to Tapered Pipe Threads

To get a hand with selection, sizing, or to have precise lengths prepped for you, please use a green button on this page to get in touch.

Before installing any piece of tubing into a Swagelok fitting, the installer should take a moment to take a look at the following items:

- Is the tubing seamless or welded?

- What is the hardness of the tubing?

- Is the surface finish is free of scratches

- Check for ovality of the tubing.

- Check the OD and ID to make sure they are free of burrs.

- Check the wall thickness to make sure it is sufficient for the pressures that the system will see.

- Check the tubing for concentricity, that is, check that the wall thickness is consistent all the way around the tubing.

Each of these issues is discussed in our article Your Checklist for Tubing Quality. If you have worries or questions about tubing please use a green button to get in touch with our team.

The pressure rating of a Swagelok tube fitting depends on the lowest rated component in the system in which it is installed. Sometimes the lowest pressure rated component is a pipe thread, a pressure gauge, or a valve. Other times it will be the pressure rating of the tubing itself, and that will vary depending on the tubing's size, wall thickness and material of construction.

To learn more, please download the literature offered at the top of this web page. (Need sales, support, or information? We are ready to help. Please click "Request Details" on this page.)

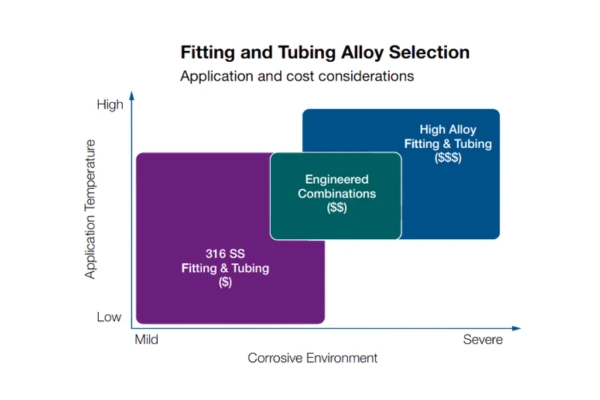

Generally it's best to use like materials. There are exceptions.

Example: if you have stainless steel tubing, use stainless steel ferrules and fittings. On plastic tubing, use plastic ferrules and fittings. The reason for matching materials is simple: You want the ferrules to be stronger than the tubing so that the ferrules can swage onto the tubing and lock into place. This video explains more:

If the ferrules are made of softer material than the tubing, you won't get that swaging action. Brass, for instance, is softer than stainless steel. So brass ferrules won't give you the full swaging action on stainless steel tubing.

There are exceptions to the rule. To learn more, please download the literature offered at the top of this web page. (Need sales, support, or information? We are ready to help. Please click "Request Details" on this page.)

When properly installed, Swagelok fittings produce a repeatable, leak-tight seal even after being reassembled multiple times. Before disassembly, mark a line along the nut and body flat and use these marks to ensure that the fitting is reinstalled properly. Please watch the video demonstration below for the proper instructions:

One advantage of the two-ferrule fitting design is the ability to reuse the body without leaks. Most of the cost of replacement is in the fittings, not the nuts and ferrules. Sometimes you don't even have to replace the ferrules.

If you have made changes in the system design, by moving a fitting to a new location or changing the tubing, you can't re-use the nuts and ferrules, but you can still re-use the fitting bodies. Even on a simple connector, you are saving a big percentage of the cost of using all-new parts. Think of a cross or a tee that is more robust - there is a huge cost savings opportunity there.

If you are in doubt, consider taking advantage of our Fitting Reclamation Program. Working together, we'll show you where it makes sense in your system to re-use and refurbish. Just get in touch using a green button on this page.

For personalized, up-to-the-minute answers to sales and support questions, please use green buttons on this page to request details/quote.

If you prefer to find answers yourself, visit products.swagelok.com, register for an account, and start exploring. Anyone can register, and completing the entire registration form will allow you to view pricing, order online, request quotes, store favorite products, assign customized part numbers, and save or forward your shopping cart. Register or log in →

For 24x7 technical support call 780-237-7109. Request the on-call Field Advisor to discuss your technical question.

For 24x7 parts call 780-437-0640. Select "Emergency Service". Request to buy outside regular hours.

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.