Products > Hose and Flexible Tubing

Swagelok Hose and Flexible Tubing

Download Swagelok® PDFs & local resource collections. Learn about Hose Advisory Services. Explore FAQs and videos. Tel: 780-437-0640.

.webp)

Download Essential Hose Catalogues

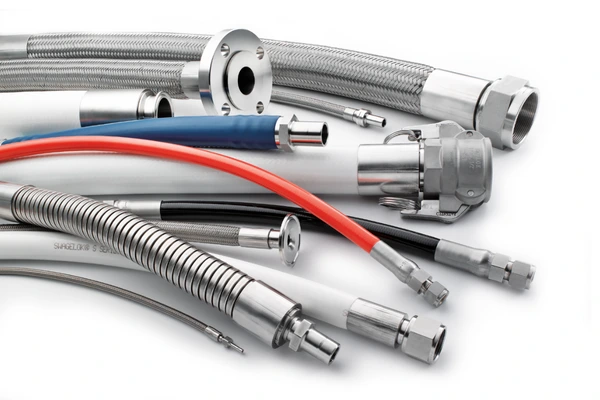

Swagelok Hose & Flexible Tubing for Every Application

Swagelok provides an extensive range of industrial and high-purity hoses featuring diverse core materials, reinforcement types, end connections, and insulation choices, catering to a wide array of applications for the conveyance of liquids and gases. Below are some of the main types:

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

Download Hose Selection & Troubleshooting Collection

The Lifetime Value of a Swagelok Hose

Why do so many engineers specify Swagelok hoses when there are cheaper brands? Because with the right hose in place they prevent repeated hose replacements, loss of profits, runtime failure, and safety incidents. Take a look at how Swagelok builds hose that performs under pressure:

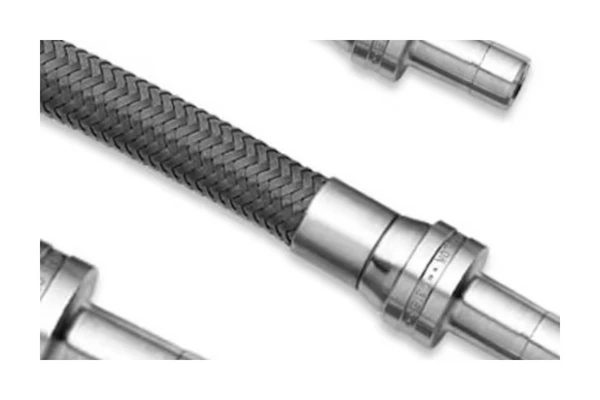

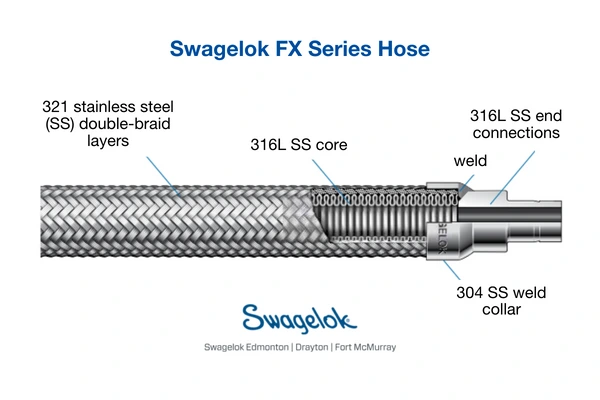

FX Series

FX hose is designed for high pressure chemical, compressed gas, cryogenic, hydrogen, marine, oil/gas, power, and pulp/paper applications. It is all corrosion-resistant metal, from the 316L stainless steel annular convoluted core to the 321 stainless steel double braid layers to the 316 stainless steel end connections, which are welded to the 304 stainless steel collar. Offered in 1/4 in. to 2 in. nominal hose sizes with a temperature range of –325 to 1000°F and working pressure ranges from vacuum to 6000 psig through vacuum to 1122 psig.

.webp)

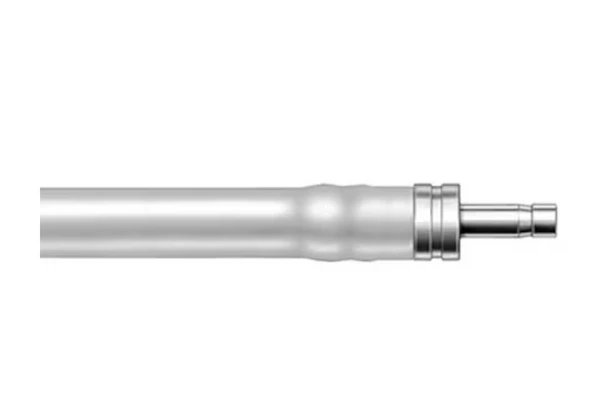

U Series

.webp)

W Series

Certifications

Expertise

Guarantee

Assembled

Inventory

Manufacturing

Materials

Reliability

Training

Download FX Series Hose Pull Sheet

Hose Advisory Services

Bring in our hose advisors to assess hose. We can recommend steps to reduce wear, maintenance, and replacement.

Maybe you want to increase the service life of your hoses. Or certain hoses are frequently failing and you can't pinpoint why. The issue might be kinking, having the wrong hose for the job, or chemical compatibility. Maybe the hose is not routed properly, there is electrostatic discharge, or lengths aren't quite right.

Swagelok Edmonton offers expert Hose Advisors who specialize in industrial hose. Get our Hose Advisory PDFs below to learn how this service works.

Download Hose Advisory Services Information

Swagelok Assemblies Increase Your Value

Instead of getting a hose or two, consider getting a fully built Swagelok assembly that exactly meets your needs.

We combine safe, reliable Swagelok components to produce assemblies for gas distribution, grab sampling, mechanical seal support, and other uses. We also build hose, bend tubing, and make filter retainer assemblies, for example. Design support, fabrication, assembly, and pressure testing are included! We can be onsite at installation too.

Frequently Asked Questions

Take an 'inside-out' approach, working from core to cover.

Start by addressing the core—the innermost layer that contacts the fluid—available in materials like nylon for low temperatures or metal for high temperatures, and then adding a reinforcement layer for strength and pressure containment.

The outer cover, with options like stainless steel or Swagelok's Fire Jacket, provides protection against various environmental factors, including temperature extremes.

Finally, choosing the right end connections, such as NPT threads or tube adapters, ensures a secure, leak-free system that meets industry standards and minimizes downtime.

To learn more, please download the literature offered at the top of this web page. (Need sales, support, or information? We are ready to help. Please click "Request Details" on this page.)

Here are five tips to prevent setbacks.

Most PTFE-lined hose failures are due to factors that can be controlled. By avoiding one or all of these pitfalls you can maximize the life of your hose.

- Right hose, wrong application—Choosing the proper end connections and designing a suitable layout should eliminate a high percentage of these failures.

- Right application, wrong hose—PTFE is one of the most chemically inert and compatible materials on earth. However, use of rubber, metal, or even PTFE-wetted parts in the wrong service can be prevented by checking fluid compatibility with wetted hose material before installation.

- External damage—Abrasion can reduce the useful life of a hose. Abrasion will even compromise the stainless steel outer braid of our PTFE-lined hoses, drastically reducing the pressure containing capabilities.

- Electrostatic discharge—Although PTFE is non-conductive it can be modified with sufficient conductivity to ground the static electric charge, eliminating a risk of catastrophic failure from charged particles arcing through the PTFE core.

- Tested hose works better—Poor quality components or choosing a hose solely on low bid can lead to high costs associated with maintenance, safety, lost fluid or compromised equipment.

To learn more, please download the literature offered on this web page. (Need sales, support, or information? We are ready to help. Please click "Request Details" on this page.)

Faulty hose routing is the leading cause of industrial hose failure.

Routing rigid tubing requires careful planning, but routing hose and flexible tubing is relatively effortless—right?

Wrong. In fact, Swagelok has thousands of data points showing a clear pattern: faulty hose routing is the leading cause of industrial hose failure. And short hose service life is costly in several ways. For one thing, too many manufacturers, processors, researchers, and other essential businesses overspend, year after year, on preventable hose repairs and replacements.

Correctly routing hose requires two things:

- Knowledge of best practices (see below)

- Commitment to act on the knowledge

Our Hose Advisory Service helps take the pressure off of you regarding hose routing. View information on the program on this page and download the pull sheet.

Here are 5 tips on guarding against permeation.

All materials are permeable to a degree, but in industrial hose applications permeation is important to consider when using PFA and PTFE materials. We recommend the following to mitigate permeation:

- Choose hose materials that are known to be resistant to permeation by the specific media being transported.

- When appropriate, choose hoses designed with barrier layers that significantly reduce permeation. These barriers can be made of materials like nylon.

- Regularly inspect hoses for signs of wear, damage, or other issues that might increase permeation. We offer a Hose Advisory service that can help.

- In cases where permeation is inevitable, venting systems can capture and safely release or contain permeated substances.

- In critical applications, it can make sense to use hoses that exceed the required specifications. It depends on the risks involved.

Swagelok Edmonton offers a Hose Advisory Program that puts our highly trained Field Advisors onsite with you. After walking the floor of your facility, learning about your unique situation, and documenting issues, we help you choose the right equipment and implement practices that extend hose life and improve hose performance.

Yes, we have a dedicated Hose Cell where we do that daily.

Our technicians manufacture hose to your specifications right here at Swagelok Edmonton shop. We can handle orders from one piece to hundreds of pieces, and offer a wide variety of hose solutions. In some cases we can build a hose in as fast as five minutes.

Our abilities don't stop with assembly. We can do a hydrostatic test, an immersion test, and pressure decay testing. A lot of hose shops just make the hose and send you on your way. We test 100 percent of the hoses we make. In the hydrostatic test, the hose is filled with water, and then sealed. We hold it under pressure as we check for leaks where the end connection is attached.

Some hoses require that we provide a test certificate, and some don't. But we can provide documentation with any hose if requested. If the need ever arises, we can trace each individual hose back to the original assembler

We have you covered with six cover options.

Hoses can be subject to a variety of outside forces that speed up wear and tear. With the right cover, the service life will be extended.

Here are some of your options:

- Fire Jacket

- Thermosleeve

- Armor Guard

- Spiral Guard

- Nanogel Cover

- Spring Guard

Please download the literature available on this page to learn more, and get in touch with our team to get a hand.

For personalized, up-to-the-minute answers to sales and support questions, please use green buttons on this page to request details/quote.

If you prefer to find answers yourself, visit products.swagelok.com, register for an account, and start exploring. Anyone can register, and completing the entire registration form will allow you to view pricing, order online, request quotes, store favorite products, assign customized part numbers, and save or forward your shopping cart. Register or log in →

For 24x7 technical support call 780-237-7109. Request the on-call Field Advisor to discuss your technical question.

For 24x7 parts call 780-437-0640. Select "Emergency Service". Request to buy outside regular hours.

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.