.png)

Improve safety and lower costs with our pressure control advisory services and gas distribution systems. Browse below and talk with us to learn more.

Gas distribution systems work to deliver gases from a high-pressure source to the facility at the pressure and flow rate required by each application. Most often built around one or a series of pressure regulation steps, gas distribution systems may have four typical subsystems: Source Inlet Connection, Primary Gas Pressure Control, Point-of-Use, and Automatic Changeover.

Swagelok's Gas Distribution Program is designed to help you:

Overlooked gas distribution system issues can result not only in loss of gases, but also in lost process efficiency, downtime, or safety hazards. When system operation is not intuitive, when leaks are a concern, or when your gas panels are difficult to service, it is time to take action to avoid compounding costs.

Specific problems could include:

Backed by 70-plus years of fluid system expertise and a global network of pressure control advisors, Swagelok offers a two-pronged solution: pressure control advisory services and gas distribution systems that help ensure facilities are operating safely and efficiently.

Our advisors, in collaboration with your team, deliver:

Our gas distribution systems are backed by Swagelok's industry-leading warranty. Plus, we support you after the sale so you can be sure your system will continue to operate with precision.

View four standard gas distribution assemblies below. The design and quality of Swagelok gas distribution systems ensures uptime, safety, and efficiency. These systems allow ease of maintenance and troubleshooting to keep systems reliably delivering required pressures and flows.

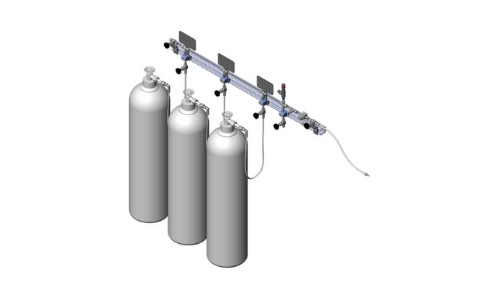

The source inlet connects the high-pressure gas source and the distribution system. It is important the inlet is built with appropriate cylinder connections, hoses, tubing, filters, and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover. For a single gas cylinder, the assembly can be as simple as a hose and connector. Multiple cylinders may require a manifold with many hoses and valves.

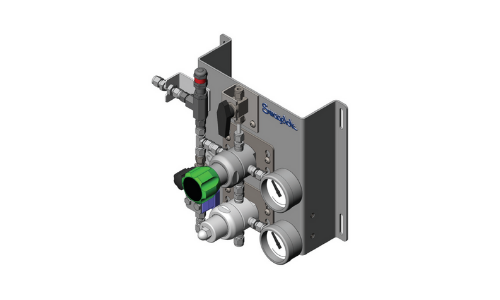

As the primary gas pressure control, the SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

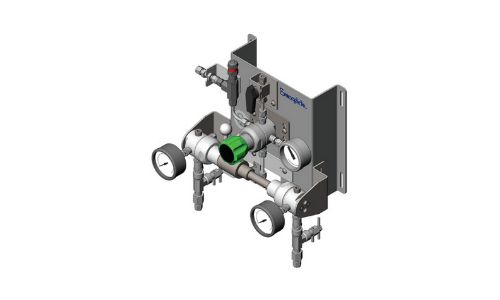

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. Our changeover station allows for custom changeover set points to help reduce wasted gas left in cylinders.

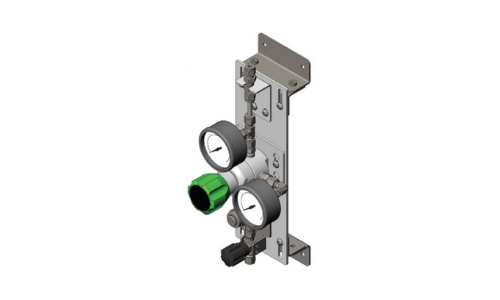

The point-of-use system provides the critical last stage of pressure control prior to the gas being used. These are often the least complex of the four main subsystems, typically having a pressure regulator, gauge, and isolation valve. Point-of-use systems give operators and technicians a convenient and accurate method of adjusting pressure to meet their test bench or equipment needs.

Evaluation, advice, and ongoing support are just as much a part of our Gas Distribution Program as the standard subsystems we offer. Swagelok provides critical analysis to inform proper regulator selection, identify system upgrades, and guide the design and assembly of standard and customized solutions.

Following a thorough assessment of your gas delivery systems, you get a detailed report showing:

At one leading chemical company, Swagelok identified ways to standardize gas panel design. They found components for purging and venting had been added over the years, resulting in unnecessary complexity. Removing critical relief valves via tapered, threaded connections during maintenance required significant labour time. And the customer’s use of different gas panels from multiple suppliers made planning ahead for replacement difficult. Through the Gas Distribution Program, this customer achieved:

Edmonton Valve's Gas Distribution Program Resource Collection puts several helpful publications in your hands, all in one step.

The collection includes:

In a hurry or have a question? Please call our office at 780-437-0640.

(Need technical help right now? Call our 24x7 Field Advisory Services On-Call Technical Support Line at 780-237-7109.)

To get started, click the green button and answer a few questions so that we can help you. There is no cost, no obligation created by requesting more information.

Download the Edmonton Valve Gas Distribution Program Resource Collection containing an application guide, brochure, case study, and more.

Please fill in information below so that a senior member of our team can help you. You choose whether to receive details by email or phone. There is no cost, no obligation created by requesting more info.

This Gas Distribution Program Resource Collection puts several helpful publications in your hands, all in one step. It includes a detailed application guide, two brochures, and a case study. Please fill in the fields below to get this free PDF.

Swagelok is a $2B developer of industrial fluid system products and services. Swagelok Edmonton is an authorized Swagelok Sales and Service Centre serving Canadian companies in clean energy, chemical, oil and gas, and other industries. Proud member of the Canadian Council for Aboriginal Business.

Tel: 780-437-0640.

Swagelok Edmonton values your privacy. This website uses cookies to enhance user experience and analyze performance and traffic. Our policies are posted here.

Login/Register | Privacy | Safe Selection | Centre Locator | Sitemap | Legal

© 2012-2024 Edmonton Valve & Fitting Inc.