Explore your options in this section and talk with us to learn more.

We understand the need for high-quality seal support systems to maximize rotating equipment uptime in petrochemical operations. When faced with seal flush challenges, you need a mechanical seal support plan or kit assembled, tested, and delivered ASAP.

Your mechanical seal support plan or kit should not only lubricate and flush seal faces while controlling pressure and temperature in seal chambers—they should also:

Edmonton Valve & Fitting can provide all of the above—and more. We adhere to all of the API 682 design standards while providing the flexibility to customize your solution to fit your Alberta petrochemical refinery needs. We have the resources and accessibility to support the needs of local refineries in central and northeast Alberta and the Northwest Territories.

With our extensive inventory and team of local Field Advisors to help deliver solutions to seal flush challenges, Edmonton Valve & Fitting is your best choice for mechanical seal support replacement services. Our seal support systems are backed by our industry-leading Limited Lifetime Warranty.

Our local presence in central and northeast Alberta allows us to provide you with locally designed and fabricated seal flush systems without the need to wait for components to be shipped from remote manufacturing facilities.

Our expert Field Advisors can perform onsite consultations to identify seal flush inefficiencies to recommend custom solutions tailored to your exact needs.

As your local seal flush system partner, Edmonton Valve & Fitting is available for onsite consultations, virtual AR-assisted onsite visits, leak detection assistance, and fluid system evaluations. Our local presence, design and fabrication expertise, and superior component quality allow us to meet the mechanical seal support replacement needs of Alberta petrochemical refineries.

When you need mechanical seal support replacement services, Edmonton Valve & Fitting is the best partner for Alberta petrochemical refineries.

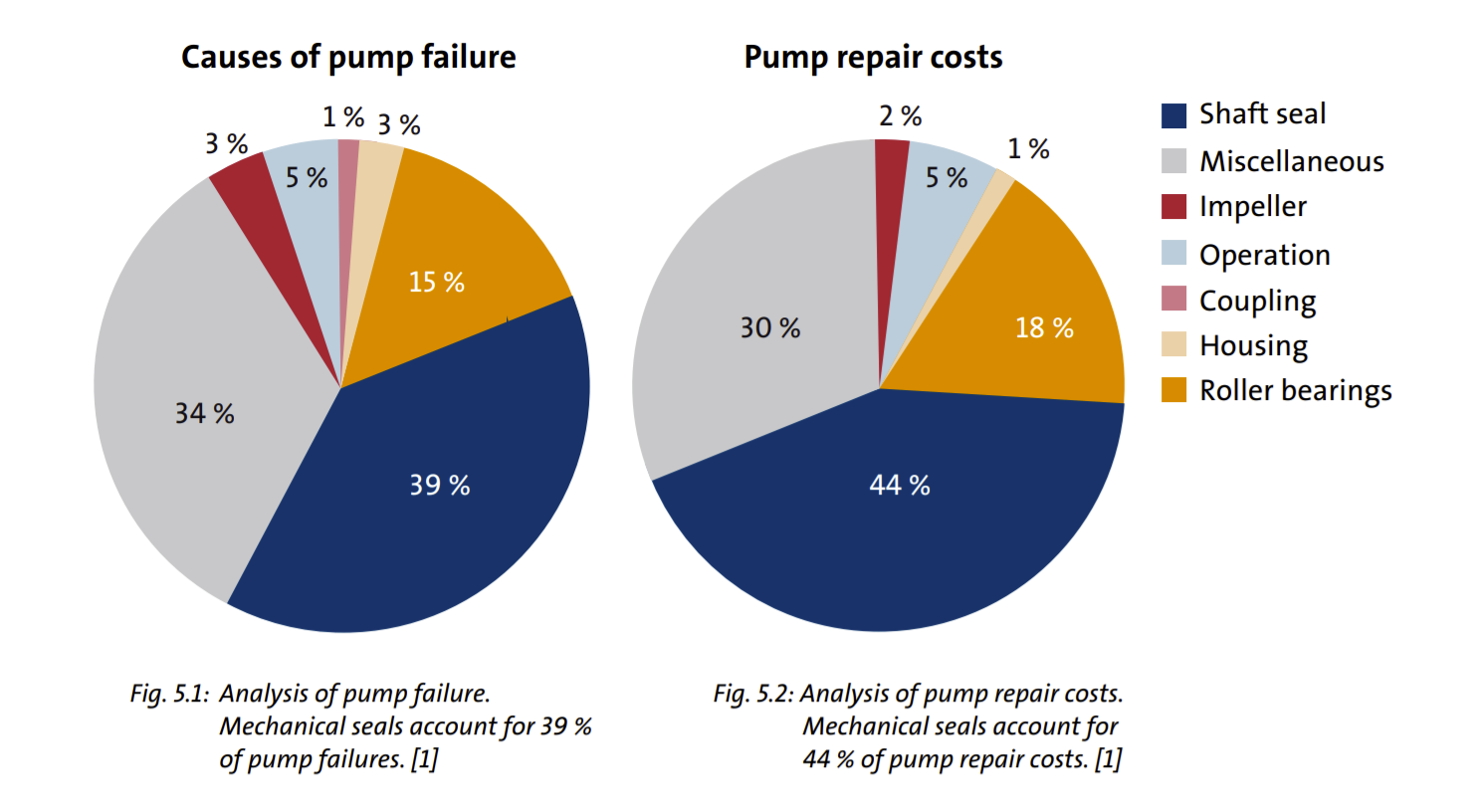

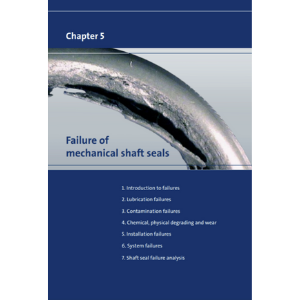

When rotating equipment fails, it’s often due to a seal failure. In fact, about 40% of all unscheduled critical pump shutdowns are caused by mechanical seal failures (Grundfos). And shutdowns are often expensive.

"The diagrams... show that shaft seal failure is by far the most common cause of pump system failure. See figures 5.1 and 5.2," writes Grundfos.

Swagelok’s seal plans maximize the life of mechanical seals and the reliability of rotating equipment by maintaining lubrication and pressure with properly conditioned fluid flows.

Screenshot of Mechanical Shaft Seals for Pumps, Grundfos, page 76, http://machining.grundfos.com

Swagelok mechanical seal support systems are:

|

|

Swagelok applied decades of fluid systems engineering expertise to make our seal plans reliable, safe, and easy to maintain. For example, our systems have the fewest possible threaded connections (where costly leaks can occur).

When we say our API 682 seal plans are better by design, we mean:

Swagelok applied decades of fluid systems engineering expertise to make our solution reliable, safe, and easy to maintain. For example, our systems have the fewest possible threaded connections. (3 min)

Proper start-up and commissioning are critical for reliable operation of mechanical seals and their associated support systems. For example, air in the system at startup can lead to issues with the seal support system. Flow can be disrupted or stopped in systems with chillers or seal pots. Air inclusions can also prevent the support system from providing the desired rate of cooling. Swagelok design options include high-point vents in the seal support system, so the system can be cleared.

API 682 recommends specific wall thicknesses for 1/2 inch (12 mm) to 1 inch (25 mm) OD tubing. While thinner-walled tubing, such as that used in general instrumentation installations, is often sufficient to handle the pressure and temperature of seal support systems, heavier-wall tubing provides extra rigidity in high-vibration service. Tubing with a heavier wall also creates systems that are more robust in areas where large pieces of equipment are being maintained and personnel may inadvertently come into contact with the tubing.

A common flow issue is clogged orifices, which can cause a loss of flush fluid to the seal chamber, resulting in seal failure. Additionally, improper circulation of buffer and barrier fluids can also cause operational issues due to lack of appropriate system cooling. Swagelok systems are designed to prevent such this and other causes of inappropriate flow.

Swagelok's API 682 standard designs incorporate all the recommended components and adhere to best practices. For better operation and service of the seal and pump, we go beyond the standards to design systems specific to your application. This includes optional isolation valves, bypass loops, and instrumentation to assist the pump operator in both maintaining the system and monitoring the health of the seal.

We offer kits and assemblies:

Kits & assemblies

To download details, go to the tab labeled "Catalogues".

Assemblies only.

To download details, go to the tab labeled "Catalogues".

Kits only

To download details, go to the tab labeled "Catalogues".

Seal plan kits (SPK) are a collection of components that are used to connect the seal support plan to the pump. Each kit contains everything needed for proper installation, including an engineered drawing. For projects or turnarounds, seal plan kits can be used to standardize how plans are connected to the pump. Kits also adhere to API best practices by showing technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

Seal plan assemblies (SPA) are panels, seal pots, or skid systems that comprise the majority of the API seal support plans. The seal plan assembly ordering numbering structure allows users to select a variety of configurations and additional system components to meet specific site or application requirements. Options and configurations not listed in the ordering numbering structure are also available. Seal plan assemblies can be ordered alone or with the associated field installation kit to provide a standard installation for site personnel.

To download details, go to the tab labeled "Catalogues".

Check out innovative components below. Go to the "Catalogue" tab to download details.

Replace threaded or welded flange assemblies with a one-piece flange adapter with integral orifice.

Reduce threaded connections and monitor temperature with integrated thermowell pre-welded into tube fitting tee.

Eliminate threaded pipe and potential leak points with a single fitting. Available in 4- and 6-inch lengths to clear the shroud.

Easily add an orifice to a flush system with the orifice union. This fitting makes welding bulky flange assemblies unnecessary.

To download details on the components shown, click "Catalogue" below or go to the tab labeled "Catalogues".

For 50 years, Edmonton Valve & Fitting has provided professional support and an extensive local inventory of Swagelok products. We offer custom solutions, applications support, ebusiness solutions, training, equipment, tools, and more. In fact, our customers have saved over $10M since 2000, as reflected in their annual VIP Reports quantifying savings in several categories.

For better operation and service of the seal and pump, we go beyond the standards to design systems specific to your application. This includes optional isolation valves, bypass loops, and instrumentation to assist the pump operator in both maintaining the system and monitoring the health of the seal.

And with Swagelok Custom Solutions from Edmonton Valve we can also:

We've gathered feedback from engineers and reliability/rotating equipment managers. Find eight examples below.

To get details on plans, components, and related information, click the 'Download' button below and fill the form. You'll receive:

We are ready to provide technical details, examples, and no-obligation estimates.

Swagelok is a $2B developer of industrial fluid system products and services. Swagelok Edmonton is an authorized Swagelok Sales and Service Centre serving Canadian companies in clean energy, chemical, oil and gas, and other industries. Proud member of the Canadian Council for Aboriginal Business.

Tel: 780-437-0640.

Swagelok Edmonton values your privacy. This website uses cookies to enhance user experience and analyze performance and traffic. Our policies are posted here.

Login/Register | Privacy | Safe Selection | Centre Locator | Sitemap | Legal

© 2012-2024 Edmonton Valve & Fitting Inc.