Share this

Choosing the Right Swagelok Needle Valve: Guidelines and 3 Examples

by Tristian McCallion on Tue, Mar 26, 2024 @ 08:03 AM

Today we focus on selecting needle valves, taking into consideration general and severe service valves along with the various stem tips available. A new video from Swagelok shows the design differences. We include links to download literature with further details and Swagelok Edmonton is happy to lend a hand with product selection.

Swagelok needle and metering valves feature straight-pattern or angle-pattern flow for low- and high-pressure service, in both brass and 316 stainless steel materials. Every metering valve is factory tested with nitrogen at 1000 psig, and shell tested.

Precisely which needle valve is appropriate for your application depends a lot on the specific requirements of the system and the preferences of the user. But let's look at how to narrow down the options.

There are two main types of needle valves to consider: general service valves and severe service valves.

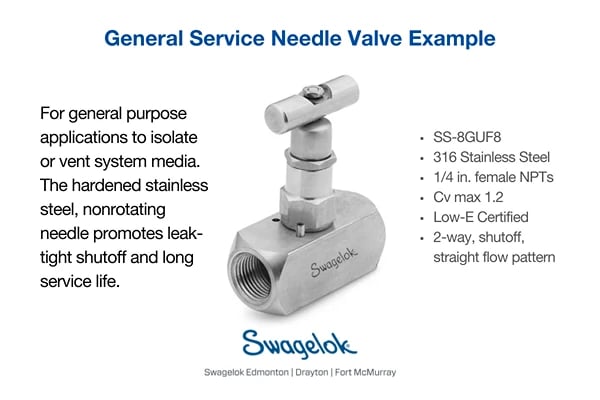

General service needle valves

General service valves feature a forged body design, with the packing positioned high on the stem, resulting in exposed stem threads to the system media.

This aspect is crucial to consider for these valves. They offer three stem tip options:

- Soft seat for environments where the risk of stem tip damage is a concern

- V stem tip for improved regulation

- Regulating stem tip for precise control, requiring more turns to operate but providing the finest regulation

An alternative option is the toggle valve, designed for situations requiring rapid opening and closing or when the valve needs to be left fully open.

Severe service needle valves

Our severe service valves are constructed from solid bar stock and feature a union bonnet design that prevents accidental disassembly. Their design keeps the packing below the stem threads, protecting the lubricant from system media.

The standard stem tip for these valves is a ball stem tip that rotates within the stem tip to minimize wear during operation. A regulating stem tip is also available for these valves for enhanced control.

A video from Swagelok steps through needle valve selection considerations:

This Swagelok video touches on general service valves, stem tips, regulation tips, and design features of severe service valves. Catalogues are available at the Swagelok Valves page here at our website. We also suggest our free Valve Selection & Sizing Resource Collection, which includes the Swagelok tutorial "Matching Valve Type to Function".

Getting help with valves

Field Advisory Services

Swagelok Edmonton offers experts trained to help customers take action on fluid system challenges. If you'd like to double-check your selection with our advisors, we are here to help. You can also talk with our Field Advisory team about analytical instrumentation, compressed gas leaks, seal flush systems, applications support, and more.

Swagelok Valve Assemblies

Some customers opt to get a fully built assembly that includes the right valve(s). The Custom Solutions team here at Swagelok Edmonton builds analytical subsystems, gas distribution systems, grab sampling systems, hose assemblies, regulator assemblies, and much more. Your assembly arrives ready to install, and is covered by the same warranty as our individual parts. Projects include design support, parts, fabrication, assembly, testing, documentation, and installation support.

|

Valve Selection & Sizing Best Practices Resource Collection

Includes STAMPED Method of Valve Selection Technical Briefing Video, a pocket guide, Matching Valve Type to Function tutorial, and other resources.

|

Related articles

- FAQ: Which is the Correct 60 Series Ball Valve?

- How a 40G Series Instrumentation Ball Valve Minimizes Leak Potential

- Swagelok's Rebuilding Kits Help You Adjust or Replace Valve Packing

- New Liquid Sampling Valve Solves Common Bottle Sampling Challenges

- The 10,000 Hour Rule and Finding Answers to Fluid Systems Technology Questions

- New Full-Bore Ball Valve Handles 6000 psig + Available for Sour Gas

- Beyond the Basics: Swagelok Ball Valve Actuation Options

- Swagelok's 60 Series Ball Valves Cover a Range of Applications

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)