Your Mechanical Seal Leak Troubleshooting Guide for SAGD Operations

by Thomas Webster on Thu, Jun 17, 2021 @ 08:06 AM

Mechanical seal leakage is typically unavoidable as seals age and develop wear. Inadequate flushing and lubrication of mechanical seals can also lead to seal damage, resulting in leaks that may presen …

Why Mechanical Seal Support Damage Occurs in Winter: Understanding the Problem and Your Potential Solutions

by Thomas Webster on Thu, Jun 10, 2021 @ 14:06 PM

Seal support systems are essential for the operation of pumping and rotating equipment, as they are designed to support a specific seal and set of process conditions by supplying either a liquid or ga …

Why an Industrial Fluid System’s Routing Matters More in Alberta, Canada

by Thomas Webster on Thu, Jun 03, 2021 @ 08:06 AM

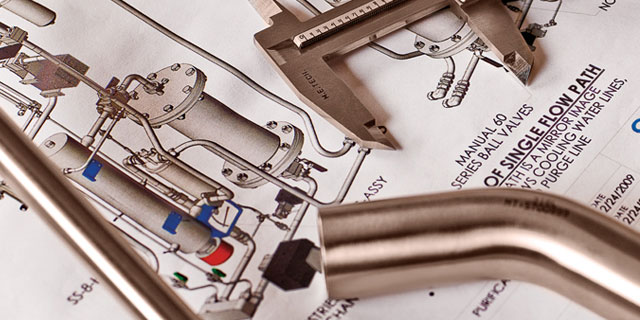

When designing facility layouts for oil and gas operations and petrochemical refineries, it is critical to consider industrial fluid systems’ routing, especially in locations like Alberta, Canada. Wit …

Managing an Industrial Fluid System’s Flow Efficiency in Colder Weather

by Thomas Webster on Tue, May 25, 2021 @ 14:05 PM

Buffer and barrier seal support plans are required for dual seals to operate. Dual mechanical seals have become more prevalent in pumping equipment to maintain higher safety and reliability standards …

Why a Seal Support System Water Flush Plan Matters

by Thomas Webster on Tue, May 18, 2021 @ 09:05 AM

Flush plans aim to maintain proper lubrication, temperature, pressure, and solids management by circulating fluid to or from a seal. A suitable flush plan should create an optimal working environment …

When Your Fast Loop Sampling System Is Not Working: A Guide to Root Cause Analysis

by Tristian McCallion on Tue, May 11, 2021 @ 10:05 AM

Fast loop sampling systems are essential during custody transfer processes. Because of the high value and large volume of the crude oil that is typically transferred, it is imperative that the samplin …