Choosing Grab Sampling Systems for Sampling of Water in SAGD Operations

by Thomas Webster on Thu, Sep 16, 2021 @ 14:09 PM

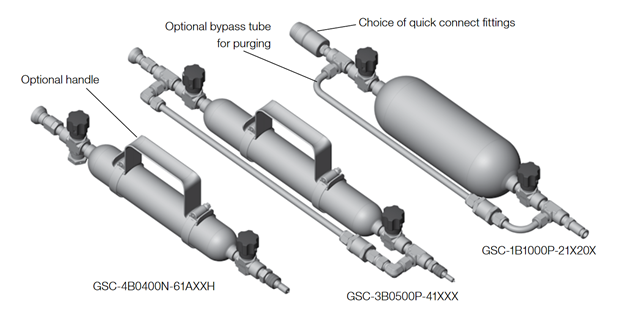

In SAGD processes, steam is injected downhole to heat bitumen, allowing it to flow to the surface. The steam returns to the surface as an oil/water mixture, which must be separated so the oil can be r …

Why Mechanical Seal Support Material Matters for Northern Alberta Oil and Gas Operations

by Thomas Webster on Wed, Sep 15, 2021 @ 09:09 AM

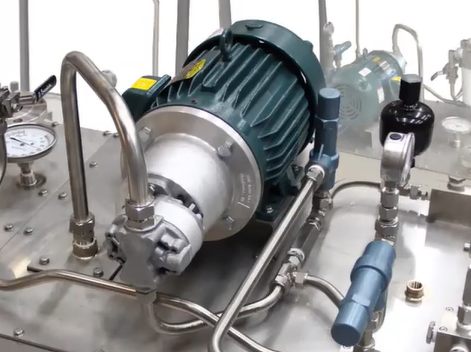

Centrifugal pumps at chemical plants and refineries rely on mechanical seals to prevent fluid from escaping. Every seal connection is a potential leak point, and leaks can lead to fugitive emissions, …

Mechanical Seal Support Failure Analysis: A Guide for SAGD Operations

by Thomas Webster on Thu, Aug 26, 2021 @ 09:08 AM

Wondering Which Seal Support Systems to Use? Options for Northern Alberta Refineries

by Tristian McCallion on Thu, Aug 19, 2021 @ 13:08 PM

Northern Alberta refineries depend on seal support systems for safe and efficient pump operation. API 682 defines a multitude of seal flush plans and their use cases—but even when you know which seal …

Top Flow Assurance Challenges for SAGD Operations—And How to Prevent Them

by Tristian McCallion on Tue, Aug 10, 2021 @ 12:08 PM

Choosing Among Mechanical Seal Support Flush Plans for Optimal SAGD Processes

by Tristian McCallion on Thu, Aug 05, 2021 @ 09:08 AM

Mechanical seal support flush plans circulate fluid through mechanical seals to maintain adequate lubrication, pressure, temperature, and solids content in the seal chamber. The flush plan creates an …