Share this

Why Traditional Cone & Thread Fitting Installation is 5x Slower Than Modern Alternative

by Katie Reid on Wed, Aug 23, 2023 @ 08:08 AM

In many critical oil and gas applications, mechanical grip medium-pressure fittings like Swagelok's FK Series offer better value than traditional cone and thread fittings. One reason is installation speed. See for yourself with a side-by-side comparison.

The typical industrial facility has thousands of fittings, and, especially in critical oil and gas applications, a portion of them are likely cone and thread fittings. When it's time to replace these fittings, consider Swagelok FK Series tube fittings. Their innovative design makes them 5x faster to install and lower cost to maintain in years to come.

A Swagelok video directly compares the steps and time to install each type of fitting:

Watch installation of each type of fitting side by side.

FK series fittings can be installed faster than cone and thread fittings, for two main reasons:

Easier joining

To ensure a seamless and secure installation, cone and thread fittings require careful coning and threading using specialized tools. It is essential to avoid any burrs, gouges, or scratches during this process. After preparing the tubes, a collar is threaded onto the tubing, and a gland nut is inserted into the fitting body to securely hold everything in place.

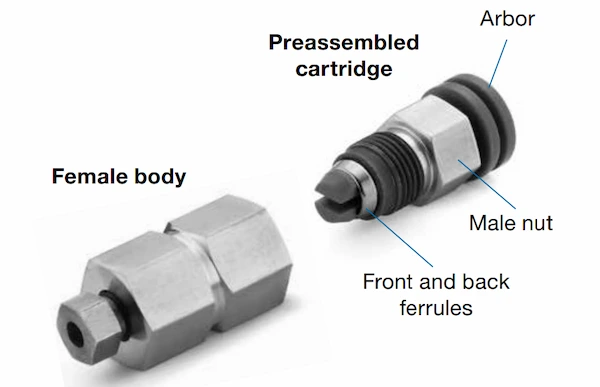

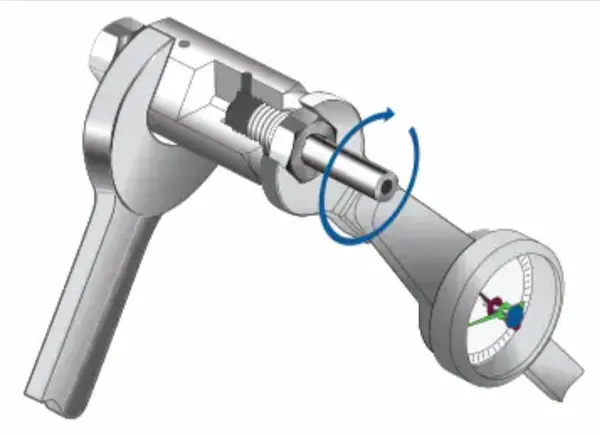

FK Series fittings are installed by threading a preassembled cartridge (which includes a nut, two ferrules, and a plastic arbor) onto the fitting body. The tubing is then inserted and marked to establish alignment, and a single 360-degree turn completes the connection. Once checked with a gap inspection gauge to ensure a tight fit, the fitting is complete and ready for use.

The simple two-piece design of the Swagelok medium pressure tube fittings and adapters consists of a female fitting body and preassembled cartridge containing the male nut and color-coded front and back ferrules on a disposable plastic arbor.

Fewer tools

To install cone and thread fittings, specialized tools and materials such as coning and threading tools, as well as cutting lubricant, are necessary. The addition of the cutting lubricant helps reduce friction during the cutting process and ensures a proper installation.

In FK Series fittings, the preassembled cartridge ensures installers have the correct ferrule orientation, visual confirmation of ferrule presence, and proper installation into the female body. Components are released only after the nut is threaded finger-tight into the fitting body.

In contrast, FK series fittings are installed with everyday tools such as a wrench and vise. No need for specialized equipment or materials.

Field Advisory Services

Swagelok Edmonton Field Advisors are glad to help evaluate current fluid systems, and can work with you virtually or visit onsite. Our goal is to provide options for enhancing efficiency, reducing operating costs, and supporting safety and emissions goals. We can check for compressed gas leaks, assess analytical instrumentation, examine grab sampling systems, and much more. Click through for Advisor bios, program information, and more.

Also see:

- Expert Swagelok Field Advisors Optimize Customer Fluid Systems

- What to Expect When a Swagelok Field Advisor Visits

- Strength and Simplicity: Medium Pressure Fittings

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)