Share this

Why Your Seal Support System’s Quality Matters—Especially in Critical Applications

by Thomas Webster on Tue, May 04, 2021 @ 10:05 AM

When rotating equipment fails, the number one culprit is often the mechanical seal. In fact, mechanical seals make up for almost 40% of pump failure causes. Additionally, mechanical seals account for almost 45% of pump repair costs.

Whether you are using a seal support system for pumps, compressors, turbines, or blowers in your operations, it’s imperative to make sure your seal support system’s quality is up to par. A quality seal support system will be reliable and easy to maintain, reducing the chances of failure and any associated costs.

Understanding the Importance of Your Seal Support System’s Quality

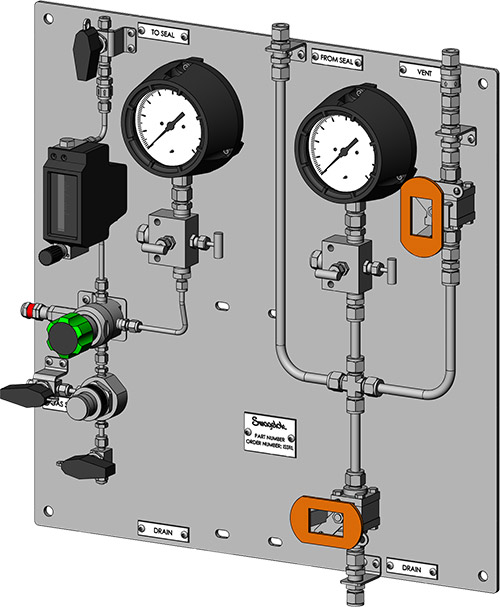

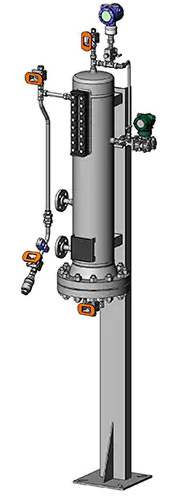

Seal support systems are designed to support a specific mechanical seal and set of process conditions, supplying either a liquid or gas to lubricate or flush contaminants from the seal. Having a seal support system that’s designed and installed according to the API 682 Standard keeps rotating equipment running efficiently.

For example, in challenging climates, such as those in central and northeast Alberta, and the Canadian territories, equipment can be left unattended for long periods of time. Because of this, refineries need a seal support system that’s reliable and easy to maintain—two of the most important factors that contribute to a seal support system’s quality.

Reliability

Having a reliable and dependable seal support system is the key to maximizing uptime. A reliable seal support system is one with high-quality components that reduce the number of leak points, an intuitive design, and is easy to maintain. Every connection in the system should be looked at as a potential leak point and a risk to overall reliability. Thus, designing a system with the minimum number of connections is optimal to reduce the potential leak points that could lead to unplanned downtime. Leak points can be eliminated by:

Having a reliable and dependable seal support system is the key to maximizing uptime. A reliable seal support system is one with high-quality components that reduce the number of leak points, an intuitive design, and is easy to maintain. Every connection in the system should be looked at as a potential leak point and a risk to overall reliability. Thus, designing a system with the minimum number of connections is optimal to reduce the potential leak points that could lead to unplanned downtime. Leak points can be eliminated by:

- Using tubing instead of piping

- Reducing the number of connections through innovative configurations

- Limiting the number of threaded connections

A seal support system with an intuitive design facilitates proper operation and helps to avoid common mistakes made when commissioning equipment. An intuitive design also supports maintainability. If the system is designed for ease of maintenance, the chance of operational error can be greatly reduced.

Maintainability

Routine maintenance contributes to a seal support system’s quality and reliability. Engineers must be able to easily perform seal support maintenance, whether that be for calibration purposes, troubleshooting a clog, replacing a component, or filling the seal pot. Performing maintenance in inclement weather—such as in central and northeast Alberta, and the Canadian territories—can be potentially hazardous. Therefore, the seal support system should be designed in a way that makes maintenance as easy and safe as possible.

A system that is constructed in a panel assembly not only allows for easier assembly, but also ensures ease of maintenance. All instrumentation around these systems should be easily readable and in an easily accessible, centralized location in accordance with the most current API 682 Standard.

When a component must be replaced, your system should be designed in such a way that maintenance doesn’t significantly disrupt operations. For example, gauges including single block and bleed manifolds allow for calibration or gauge replacement while maintaining system operations. Refilling a seal pot utilizing a seal pot fill tube eliminates the need to shut down the pump, wait for the equipment to cool, and send someone to manually refill the pot. This design can save time and mitigate safety risks.

Rely on Expertise and Experience to Improve Quality

The expertise and experience from local experts who have a deep understanding of seal support system applications is truly invaluable. Edmonton Valve & Fitting is well-versed with the requirements to maintain seal support quality in challenging climates—such as those in central and northeast Alberta, and the Canadian territories—and is readily available to provide Field Advisory Services to ensure you have the right seal support system.

The expertise and experience from local experts who have a deep understanding of seal support system applications is truly invaluable. Edmonton Valve & Fitting is well-versed with the requirements to maintain seal support quality in challenging climates—such as those in central and northeast Alberta, and the Canadian territories—and is readily available to provide Field Advisory Services to ensure you have the right seal support system.

We can help you determine whether your system requires a component upgrade, or we can even create a custom locally fabricated system to perfectly fit your needs. With the implementation of all of the best practices of the most current API 682 Standard and top-of-the-line components backed by our best-in-class Lifetime Warranty, Edmonton Valve & Fitting is the sure way to your seal support system’s quality.

780-437-0640.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (67)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (41)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- Safety (6)

- winterization (6)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)