Share this

by Thomas Webster on Mon, Feb 14, 2022 @ 09:02 AM

An inability to control system pressure to an exact degree can slow down flow rate immensely, and pressure levels beyond system capabilities can cause damage to equipment, property, and operators.A complex network of components must be employed to be able to fine-tune pressure demands to local fluid networks and effectively contain the system in the event of a necessary shutdown.

While their application generally fulfills similar roles—that of pressure reduction—the system application of these components are completely different. To settle the confusion between the pressure regulator vs. pressure-reducing valve, it is important to dive into the separate uses of each device.

Efficiency and safety

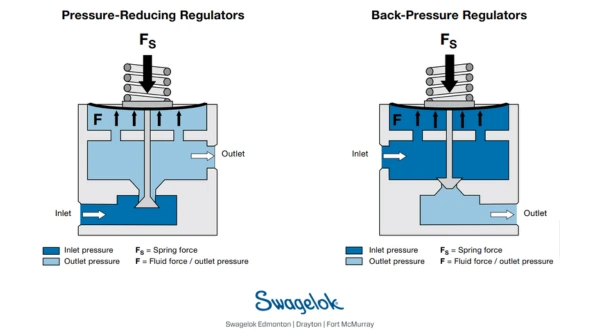

Pressure regulators and pressure-reducing valves play two separate yet critical roles in system operations. The pressure regulator acts to maintain system efficiency by ensuring the pressure upstream or downstream is held at a specific level. Two types of pressure regulators, pressure-reducing and back-pressure, can help achieve this in two ways:

- The pressure-reducing regulator holds outlet pressure constant with a potentially variable inlet pressure, while

- The back-pressure regulator features a set pressure which will cause the regulator to open once the inlet pressure exceeds it.

Maintaining a specified pressure is necessary to keep processes running smoothly and protect equipment that may be sensitive to extreme pressure levels and spikes.

Pressure regulators

Pressure regulators operate on the interplay of three internal mechanisms: the load, sensor, and control.

Illustration of two types of regulators. Visit our new 2024 Regulators Page for additional illustrations, essential literature, local answers to common regulator questions, and more.

- First, a load is placed on the regulator via spring- or gas-fed dome to provide a counterforce to the fluid pressure.

- A sensor, either a diaphragm or piston, interfaces between the externally applied load and the internal fluid pressure.

- Finally, the poppet acts to mediate any difference between the applied load and the fluid pressure.

At this point, the operations of the two types of pressure regulators will diverge. When the pressure is equal to or slightly less than the applied load, the poppet will open to reduce outlet pressure in a pressure-reducing regulator.

Meanwhile, the back-pressure regulator’s poppet will remain closed until the force of the inlet pressure increases above the set load. At this point, the poppet opens to reduce inlet pressure to the set level.

Pressure-reducing valves

Like pressure regulators, there exist multiple styles of pressure-reducing valves. Notably, the pressure relief valve serves to enhance the safety of a system by enacting failsafes and control.The relief valve serves as an escape route for pressure build-up once a set pressure is exceeded to prevent damage to equipment and operators. The valve creates a path of least resistance for pressure to flow out of the main line of the system.

In non-hazardous applications, the valve could vent directly to the atmosphere; alternatively, the fluid could be returned to the inlet or a storage reservoir with a bypass valve.

Pressure relief valves can take the form of proportional relief valves. The proportional relief valve gradually opens to reduce pressure and closes once pressure falls back below a set point. Similar to setting the load on a pressure regulator, a set screw is adjusted to reach a desired pressure for operation. Physically, the set pressure is demarcated as the point at which upstream flow first occurs; conversely, resealing pressure is the point at which upstream flow ceases.

Examples of relief valves. Our 2024 Valves Page offers essential literature and more.

Blowdown is the percentage ratio of the resealing pressure to the set pressure. As the set pressure increases, blowdown will increase as well. The relief valve will close once it reaches its reseating pressure.

For some proportional relief valves, manual override handles are available that allow an operator to bypass the set pressure of the valve without changing the value of the set pressure. The manual override therefore provides a safety redundancy, with the added benefit of preserving default settings.

Bleed valves and purge valves are two additional styles of pressure relief valves that might find use in a fluid system. A bleed valve may be used in conjunction with manifolds or gauge valves to vent pressure to atmospheric levels. This could be due to maintenance on the line or calibration of control devices.

To ensure a sufficiently low level of fugitive emissions, bleed valves should be API 624 certified to ascertain that the valve did not leak at or above 100 ppm at any point during third-party verification. The purge valve style encompasses bleed, vent, and drain valves in a manual configuration. A vent hole within the valve bleeds excess fluid from the system.

Getting help with pressure control & flow control

Whether it’s clarifying topics such as “pressure regulator vs. pressure-reducing valve” or auditing your fluid system for leaks, Edmonton Valve & Fitting offers the knowledge and products for optimal performance and safe employees.

Swagelok supports the most critical applications and industries on the planet. You can find our products at the bottom of the ocean, on the surface of Mars, and in tens of thousands of industrial plants worldwide. Our team has particular strength in fluid systems applications for conventional oil and gas, steam-assisted gravity drainage (SAGD), chemical and petrochemical refining, alternative fuels, power generation, and research.

We offer four ways to get in touch at our Contact Us page. Please click below: