Share this

Finding the True Cost of Compressed Gas Leaks in Dollars (UltraView Demo)

by Katie Reid on Tue, Jun 27, 2023 @ 08:06 AM

We are now faster and more thorough than ever at helping customers achieve leak-free systems, which can slash energy use and other costs.

Hundreds of Canadian industrial facilities around Edmonton, Fort McMurray, and Drayton Valley have realized millions of dollars in savings in recent years from our Compressed Gas Leak Detection Service. In 2023, we've improved this service by investing in advanced technology for leak detection that enables Edmonton Valve Field Advisors like James Dickie to show customers in real time where leaks are and what they cost.

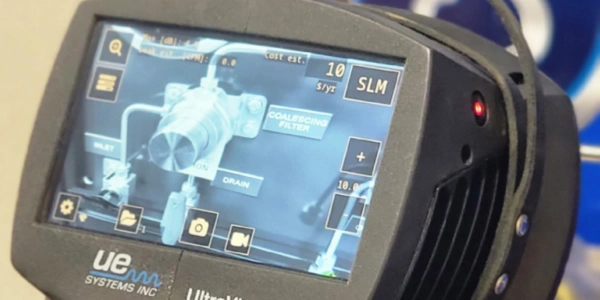

In this clip James Dickie discusses the latest ultrasound technology we use in compressed gas leak detection. The ultra-sensitive equipment can hear the sound of escaping air, and translate that into data and images for a trained inspector. Ultrasound is fast too. Our team almost always finds leaks during a one hour demo (see below) then, if hired, can usually inspect a moderate size industrial facility in a single day. For more info, get our Leak Detection with UltraView® Pull Sheet. |

"In 99 out of 100 cases, if we get a chance to look, we find leaks," explains Dickie, reflecting on 20+ years working with Swagelok customers. "We show the dollar cost of each leak per year, and what the cause is. A fix might take their technician a couple of hours. That's why this service typically pays for itself many many times over."

Even if only compressed air is leaking, stopping leaks cuts kilowatt hours (KWh) consumed to run air compressors. "If helium, argon, hydrogen, or another gas is leaking, savings from leak mitigation will be exponentially higher," adds Dickie.

Air can leak at threaded connections, quick-connects, hoses, valves... anywhere that a human interfaces with the line has the potential for an air leak.

Our Custom Solutions manager Tristian McCallion, who's served hundreds of Swagelok customers over more than three decades, once estimated that systems that have not been thoroughly inspected for leaks lose 25% to 30% of their compressed air through leaks, on average.

And whatever amount of energy is in a compressed air line, it takes many times more electrical energy to get it there. (Think about the last time you used a bicycle pump. The higher the pressure in the system, the hotter the pump gets. The same thing happens with an air compressor: It generates a lot of heat to get the line pressure up to where you want it.)

"Fixing air leaks not only eases the load on the air compressor, it means you can put off buying additional equipment as the old compressor nears capacity," points out Dickie.

Request a free demo at your facility

How much money are you losing to leaks? Allow us to visit for a one-hour demo and we'll find savings opportunities. No cost or commitment. |

After we conduct an onsite inspection, we can help quantify each issue's impact on your operation, factoring in severity, safety concerns, energy costs, emissions, product quality, and several other factors. The report you receive is packed with detail including photos of each leak, its root cause, and more.

Can we answer any questions? Please get in touch:

In addition to regular contact options, we offer 24x7 On Call Technical Support at 780-237-7109. Just dial the number and request the on-call Field Advisor.

Also see:

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)